Revolutionizing Construction: Hybrid Excavators

Hybrid technology has a long and

fascinating history that dates back to the early 1900s when Ferdinand Porsche

developed the first hybrid car. The vehicle was a petrol-electric hybrid that used

an electric motor to power the front wheels and a petrol engine to power the

rear wheels. The system was ahead of its time, but the technology was widely

adopted decades later.

The Rise of Hybrid Excavators

In recent years, hybrid technology has gained

renewed attention due to the need to cope with global warming and rising fuel

prices. The construction industry has been particularly interested in hybrid

technology because of its significant fuel savings and environmental benefits.

Hybrid excavators, in particular, have been gaining popularity due to their

fuel efficiency and versatility.

The First Hybrid Hydraulic Excavator

One of the most significant developments in

hybrid excavator technology came in 2008 when Komatsu introduced the world's

first hybrid hydraulic excavator. The machine, called the PC200-8E0, was a

20-ton class hybrid excavator that used an electric swing motor, a

generator/motor, an inverter, and a capacitor to reduce fuel consumption by up

to 25%. The machine was a major milestone in developing hybrid excavators and

paved the way for even more advanced models.

Improvements in Hybrid Excavator

Technology

Since then, Komatsu has continued to

innovate and improve its hybrid excavator technology. The HB335/HB365-1, for

example, boasts even better fuel economy and improved capabilities. This 30-ton

class hybrid hydraulic excavator was developed to extend the fuel economy

advantages of earlier models to the larger 30-ton class. In addition, it

features a large, high-definition multi-monitor and more detailed KOMTRAX

information, making it easier for operators to monitor the machine's

performance and fuel consumption.

The Science Behind Hybrid Excavator

Technology

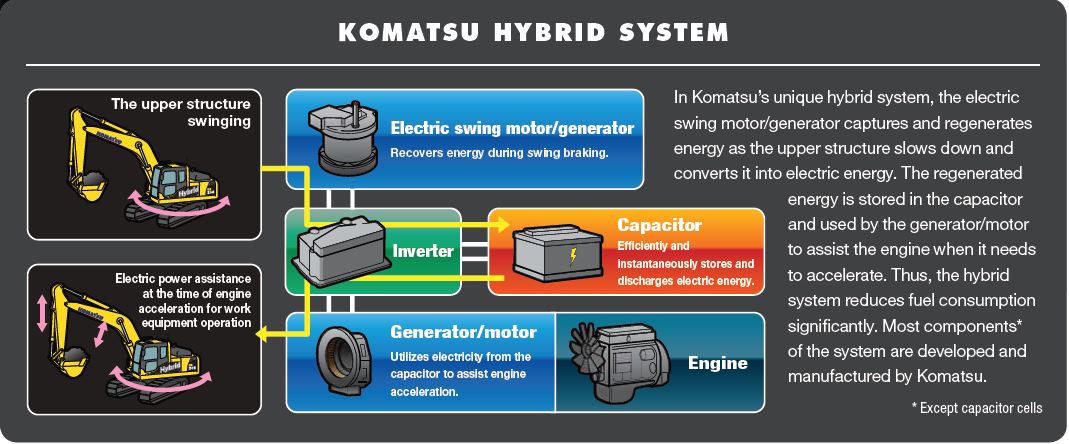

One of the standout features of the hybrid

system used in the HB335/HB365-1 is the use of a capacitor to allow electric

energy to be efficiently and instantaneously stored and discharged. This

results in more efficient use of energy and a reduction in hydraulic losses.

The generator/motor used in the machine is positioned between the engine and the

hydraulic pump for high transmission efficiency. It serves as a generator to

charge the capacitor while supplying electric power to the electric swing motor

during swing acceleration.

Hybrid excavators are becoming more popular in construction due to their fuel efficiency and environmental benefits. Komatsu has been at the forefront of hybrid excavator technology, introducing the world's first hybrid hydraulic excavator in 2008 and continuing to innovate and improve its technology. Using electric and hydraulic power in hybrid excavators allows for a more fuel-efficient and environmentally friendly solution to construction needs while maintaining the same level of performance as traditional machines. Furthermore, as emission control regulations become stricter, hybrid excavators will become even more popular and widespread in the construction industry.

. . .

06/03/2023

Comments

Post a Comment